A peaking interest in operations efficiency has commercial property developers, architects, and many other parties interested in the specific benefits of commercial floor mat installations. It is undeniable that floor mats aid in accident prevention by adding a layer of “grip” on otherwise smooth floor surfaces. Yet the benefits of commercial matting extend far beyond risk prevention. In fact, businesses often experience improvements in overall facility cleanliness after installing commercial matting systems at all major points of ingress and egress.

The following longitudinal study was created during the spring of 2011 to examine the impact of recessed grill mat systems on the interior cleanliness of a facility, as measured by debris accumulation, indoor air quality (IAQ), and the (diminishing) need for supplemental manual cleaning.

Notice of Privacy: In no other industry is cleanliness so intricately tied to the success or failure of a business than in hospitality and food service. For this reason, Eagle Mat and Floor Products reserves the rights of non-disclosure and indemnification of the participating business and parties of this study.

Abstract

The following study takes place at a food service restaurant in Western Pennsylvania. In spring of 2011, the 2,890 square foot restaurant retrofitted their entryway with a recessed grill Pedimat system. Prior to the installation, the facility experienced heavy dirt and debris accumulation on floor spaces and within the filters of the building’s air conditioning units. A team of two was employed to routinely sweep and clean all entry, dining, and restroom areas. The main areas of the facility and their corresponding areas were measured as follows (rounded to the nearest whole):

Square Footage (Total): 2,890

Square Footage (Fixtures): 1,036

Square Footage (Cleanable Floor Space): 1,854

Evidence supports each of the three hypotheses set forth by this study. First, the installation of the recessed grill mat system captured a majority of incoming debris, amounting to 51.39% (H1). Second, the increased containment of debris at the entrance of the facility reduced the need for manual cleaning by the facility cleaning crew by 21% (H2). Finally, the increased containment of debris within the recessed floor mat system lead to a corresponding improvement in indoor air quality (IAQ), as measured by a 35.15% decrease in total debris gathered by facility air filters (H3).

Process

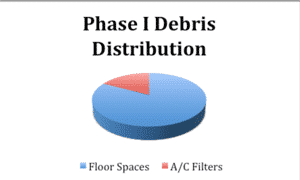

The Eagle Mat IAQ Case Study was conducted in two phases, each lasting 4 weeks, or 28 consecutive operating days. In Phase I, there was no commercial matting systems installed at the entrance of the facility. Data was gathered on the volume and distribution of dirt, food, and miscellaneous debris within the facility. All contents from floor spaces and air filters were gathered, classified, and summed according to the day and location from which they were collected. Data on debris accumulation were collected each day and totaled at the end of each week using the Quality Control Parameters detailed in the subsequent section below.

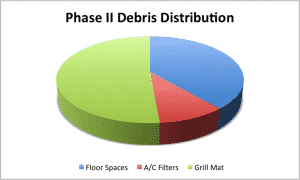

Next, a 7/16” Recessed Grill Pedimat was installed within the interior floor space of the primary entryway after the completion of Phase I. In total, the recessed grill system measured 6’ x 4’ x 7/16”.

Phase II of the study began immediately after the installation of the recessed grill mat. Data on debris accumulation were collected each day and totaled at the end of each week using the same Quality Control Parameters detailed below.

Quality Control Parameters

The following parameters were set to ensure the accurate and indiscriminate collection of data throughout the duration of the study:

1. A crew of 2 individuals served as cleaning staff through both Phases I and II of the study.

2. Debris were collected using push brooms, dust mops, dust pans, and an industrial grade Shop-VacÒ wet/dry vacuum.

3. Instruments mentioned above were used exclusively for gathering debris during this study. Other tools and cleaners were used for the general cleaning of appliances, cookware, tabletops, and other fixtures.

4. During Phase I, cleaning staff collected debris from the floor spaces of the entry, dining, and bathroom areas, as well as the A/C unit filtration compartments at the conclusion of each business day.

5. Debris were weighed using a 4100 x 0.01 gram digital scale. Note: Scale calibrated daily.

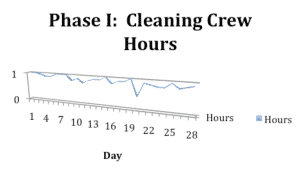

6. Cleaning crew logged total number of hours spent cleaning during the conclusion of each day during Phase I.

7. During Phase II, debris was collected from the following areas at the conclusion of each business day: the recessed grill mat, the main floor spaces of the entry, dining, and bathroom areas, and the A/C unit filtration compartments.

8. Debris were weighed using a 4100 x 0.01 gram digital scale. Note: Scale calibrated daily.

9. Cleaning crew logged total number of hours spent cleaning during the conclusion of each day during Phase II.

Case Study Findings

The data collected after the twenty-eight consecutive operating days of Phase I illustrated a 82.75% to 17.25% distribution of debris across floor spaces and air filters, respectively. Data also indicated that the cleaning crew was required to spend an average of 53 minutes to keep the floor spaces of the facility in good standing with both internal and Pennsylvania state-mandated Health Codes.

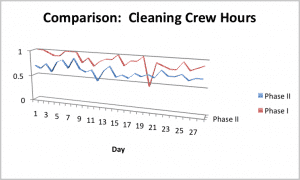

At the completion of Phase II, after the installation of the recessed grill mat system, data demonstrated that the distribution of debris had shifted to just 38.70% and 9.91% across floor spaces and air filters, respectively. An overwhelming 51.39% was contained within the recessed grill mat. Phase II was also characterized by a sharp decline in the time required of the cleaning crew to maintain good standing with regard to internal and state-mandated Health Codes.

Download the IAQ and Facility Cleanliness Case Study

Readers are encouraged to download the Eagle Mat Improving IAQ Case Study. Contained in the document are complete data sheets that track the daily distribution of debris, cleaning crew work hours, and added case study commentary.